In supercritical fluid technology, extraction has been the most studied and applied application. This may be the reason why people may have the misled notion of supercritical extraction being a simple matter. Earlier applications were in the field of food & pharmaceuticals processing such as decaffeination of coffee beans, extraction of vitamins and medicinal ingredients. Even though the process efficiency and desirability was excellent, the cost of operation was also high, thus making the applicability of the process somewhat limited to the field of relatively expensive material processing.

In supercritical fluid technology, extraction has been the most studied and applied application. This may be the reason why people may have the misled notion of supercritical extraction being a simple matter. Earlier applications were in the field of food & pharmaceuticals processing such as decaffeination of coffee beans, extraction of vitamins and medicinal ingredients. Even though the process efficiency and desirability was excellent, the cost of operation was also high, thus making the applicability of the process somewhat limited to the field of relatively expensive material processing.

Dr. Lee’s group was one of the pioneers that made the conventional high-pressure supercritical fluid technology an emerging process technology that has diverse commercial significance. In the field of supercritical fluid extraction, Dr. Lee’s group applied the process engineering principles that are based on thermodynamic and transport properties of supercritical fluids, to a wide variety of industrial processes. They include:

- low-temperature extraction of biologically and medicinally active ingredients from specific plant matters under nontoxic environment

- nutrient extraction from biological sources

- food and beverage processing

- cleaning of mechanical parts

- ultrapurification of residual impurities from synthetic materials

- removal of solvents from various chemical/ceramic/polymeric materials.

- drying without using difference in vapor pressures

- devulcanization of spent rubber

- degreasing/cleansing chemical and polymeric parts

- defouling of process catalysts (in-situ and ex-situ)

- catalytic surface preparation and/or chemical modification of catalytic ingredient

- organodesulfurization of coal

- removal of organic nitrogen from coal

- extraction of valuable chemicals from coal

Keys for success in these processing technologies are in the resultant selectivity nd product purity, process synergism, severity of imposed conditions, process yield, exclusivity of treatment option, and system scalability. Since most of the process applications are proprietary in nature, details of each process application by the ChemTech team cannot be disclosed here. However, striking and major findings in these processes share one or more of the following merits:

- synergistic use of co-solvent systems

- optimized outcome

- processability and scalability

- capitalizing on dipole and quadrapole moments

- benefits of high-pressure process engineering

- environmental benefits of no VOC & cleanness.

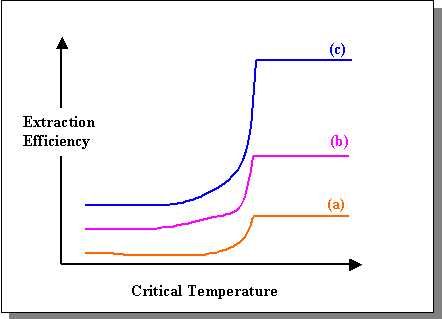

Choice of ideal solvents for SCFE is based on the following figure:

- any supercritical fluid

- when there is chemical synergism between the fluid and the chemical to be removed.

- when there is physical and chemical synergism among the fluid, chemical, and substrate.

Needless to say, the best choice of the supercritical fluid would be from case (c). It is even more so, if the chosen fluid is inexpensive, nontoxic, and fully reusable. However, discovery of a SCF system that could achieve (c) is not always straightforward or a simple matter.

We have developed a supercritical coal desulfurization process that is based on binary and ternary supercritical fluid systems. Furthermore, the technology of exploiting the synergistic benefits of co-solvents is also developed and expanded to many other chemical process treatments.

- S. Lee and V. Parameswaran, “Extraction of Organic Sulfur from Coal by Use of Supercritical Fluids”, U.S. Patent No. 5,080,692, January 14, 1992.

We have nearly perfected this process research and acquired a great deal of experience handling both small & medium-sized scales. We have five self-peripheraled supercritical fluid extraction systems in our laboratory.

If you would like to discuss about or sponsor potential R&D projects and need further information, please contact us.